Selection Of Crane Duty Motors (On photo: Single girder overhead traveling crane - max. 12.5t, 4-30m of Demag Cranes & Components via DirectIndustry.com)

Continued from second part: Selection Of Crane Duty Motors (Part 2)

Derivation Of Cyclic Duration Factor From Different Duty Cycles

S3 – Intermittent Periodic Duty

S3 - Intermittent Periodic Duty

N = Duration of motor operation under rated conditions

R = Duration of motor at rest and de-energised

ØMax = Maximum temperature attained during Duty cycle

Unless otherwise specified, the duration of the duty cycle is 10 minutes. The recommended values for CDF are 25, 40 and 60 percent.

S4 – Intermittent Periodic Duty with starting

S4 - Intermittent Periodic Duty with starting

D = Duration of starting

N = Duration of motor operation under rated conditions

R = Duration of motor at rest and de-energised

ØMax = Maximum temperature attained during Duty cycle

S5 – Intermittent Periodic Duty with starting and breaking

S5 – Intermittent Periodic Duty with starting and breaking

D = Duration of starting

N = Duration of motor operation under ratedconditions

R = Duration of motor at rest and de-energised

F = Duration for electric braking

ØMax = Maximum temperature attained during Duty Cycle

Starting Of Crane Duty Motors

The squirrel cage motors are started with direct-on-line starters in most of the cranes. Few cranes, operated more or less on continuous basis, are found operated through a variable voltage variable frequency (VVVF) drive.

For intermittent duty cranes, provision of VVVF would be costly affair.

The slip-ring or wound rotor motors are usually started by means of variable resistance in the rotor circuit to get required starting torque at reduced starting current. The value of external starting resistance can be calculated as under.

K = Constant depends on line voltage drop; varies from 0.6 to 1.0. Generally a value 0.8 can be considered.

VR = Rotor voltage (Volts)

IR = Rotor Current

TFL = Full load torque (kg-m)

TLR = Locked Rotor (Starting) Torque

Rrt = Rotor resistance in Ohms per phase

Rext = External rotor resistance per phase to be added (Ohms) to get torque TLR at stand still.

Rrt is generally small compared to Rext and may be neglected. However, if required, approximate Rrt can be calculated by following relation:

The starting torque can be increased up to the value of maximum torque available for that particular design. Usually, it is possible to obtain the starting torque as high as 2.5 times the normal torque.

Selection Of Motors

Choice of cage and wound motors may be based on the following criteria.

Squirrel Cage Motors may be used for various applications as follows:

- The driven equipment is to be accelerated rapidly with a fixed sequence of operation and uniform load conditions, e.g. mechanical workshop crane.

- If the load conditions are almost identical for both directions of rotation, e.g. long travel or cross travel of gantry crane.

- In the cranes, which are running at single speed without speed control.

- If site conditions are dusty, corrosive, these motors with totally enclosed fan cooled construction would be robust and would provide services with least maintenance.

- Where the cost factor is to be considered, as cost of cage motor is less than that of slip-ring motor;

- The squirrel cage motors for crane duty are available normally up to 250M frame size.

Slip-ring motors may be used for various applications as follows:

- Where very precise speed control is required for the crane, e.g. inching, slow and fast handling of load during hoisting and lowering, alignment of crane over a furnace opening, etc.

- In case of non-uniform loading conditions and operation is to be carried out in nos. of sequences.

- The cranes are required to perform large number of starting and reversals during operation.

- The cranes are required starting torque of more than 2.5 times the rated torque in general.

Selection

The crane duty motors are always supposed to operate under varying load conditions and sequential switching due to requirement of handling materials of varied weights (i.e. loads).

Many continuous duty motors even operate under varying load conditions due to chemical process requirements.

Selection made on this basis also provides equally effective and satisfactory operation.

Thus as an alternative, it is better to select the motor having rating slightly lower than the peak anticipated load and let it be operated at overload for a short time duration, rather than selecting the motor of high rating that would operate at full capacity for only a short period providing optimum efficiency only for that much duration. Only concern for motors operating at higher than its rating is the thermal capacity of motor, which determines the speed of degradation of the winding insulation.

Applications of various factors discussed in foregoing paragraphs combined with this suggestion would provide better result. However, accurate rating is very difficult to determine for crane duty applications.

CONCLUSION

Most vital and primary technical consideration for selection of the motor for any particular application is the torque required by the load during starting and acceleration periods, especially the relationship between the maximum torque or breakdown torque generated by the motor and the start-up torque or locked rotor torque for both periods.

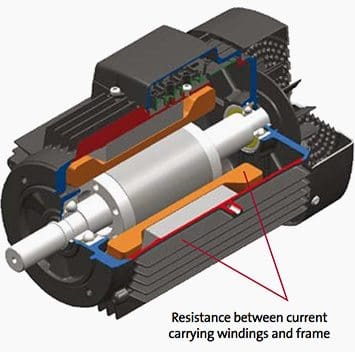

The thermal capability of motor is determined based on the duty / load cycle. Additionally, where the totally enclosed fan cooled (TEFC) motor is operated with speed variations, the cooling may be insufficient when the motor is operated at speeds below its rated value.

If the ambient temperature is more than 40°C, derating factor would affect the selection of motor. Good estimate of the switching frequency can help in selecting the appropriate motor for the proposed duty cycle.

Reliability is of prime importance in all the services, however, it is general practice to grossly oversize the motor unnecessarily for better reliability, which results into sub-optimal energy performance. Better understanding of the power system and knowledge of operating parameters can certainly aid in reducing over sizing with no adverse effect on reliability.

References:

- Efficient Electric Motor Systems Handbook, by Todd Litmann

- IS:12824-1989; Types of Duty and Classes of Rating Assigned to Rotating Electrical Machines

- The Technical Literature of Indian Motor Manufacturers